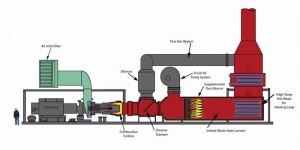

A large university in Canada awarded Indeck Keystone Energy a contract for the supply of our waste heat high temperature hot water generator for use in their combined heat and power cogeneration plant in an effort to reduce CO2 emissions by 50%. The Indeck high temperature hot water generator converts the waste gas stream into 200 MMbtu /hr of hot water heat supplied to the universities' campus heating system. Indeck's scope of supply included all equipment downstream of a Solar Titan 130 gas turbine including an integral duct burner and flue gas bypass system for operational flexibility and ability to supply campus heat in cogeneration, supplemental, and heating only mode via fresh air firing. The complete system is currently operating successfully, meeting all performance and emission targets. The fuel once used to heat campus is now used to generate 12 MW of electricity with campus heat being recovered from the combustion turbine's waste gas.

Waste Heat Boilers

Servicing the needs of our combined cycle customers has allowed Indeck Keystone Energy to become exceptionally qualified in the WHRSG market. Indeck Keystone Energy’s WHRSGs cover a wide variety of applications. Installations featuring Indeck Keystone Energy’s WHRSG can be found within the United States and throughout the world.

Offering a wide range of waste heat recovery applications.

Offering a wide range of waste heat recovery applications.

Waste Heat Boiler Applications Include:

- FCCU

- Cement Kiln

- CO Gas

- COG

- Incinerators

Indeck Waste Heat Recovery Boilers

Recent Projects

Correctional Institution Combines Heat and Power using Indeck's incline HRSG

A correctional institution in the US awarded Indeck a contract for the supply of a Heat Recovery Steam Generator (HRSG) system with auxiliary equipment to generate steam from waste gas. The Incline HRSG reclaims waste heat from a Centaur 40 gas turbine and supplies 19,200 PPH / 135 PSIG steam to the prison for heating and process users. The boiler and auxiliary equipment were delivered and were successfully started up.

A correctional institution in the US awarded Indeck a contract for the supply of a Heat Recovery Steam Generator (HRSG) system with auxiliary equipment to generate steam from waste gas. The Incline HRSG reclaims waste heat from a Centaur 40 gas turbine and supplies 19,200 PPH / 135 PSIG steam to the prison for heating and process users. The boiler and auxiliary equipment were delivered and were successfully started up.