Stationary Grate Stokers

Features

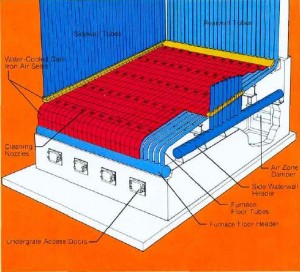

Stationary water-cooled grates, designed for burning a variety of solid fuels with low ash content, are bolted to the furnace floor tubes. The grate, constructed of best quality, heavy-duty, heat-resisting cast iron alloy, have uniformly spaced, tapered, self-cleaning air metering openings and are water-cooled for maximum grate protection.

Stationary water-cooled grates, designed for burning a variety of solid fuels with low ash content, are bolted to the furnace floor tubes. The grate, constructed of best quality, heavy-duty, heat-resisting cast iron alloy, have uniformly spaced, tapered, self-cleaning air metering openings and are water-cooled for maximum grate protection.- The refuse feeding chute for the fuel distributor is constructed for large capacity, continuous flow.

- A high pressure air duct continuously supplies transport air to the solid fuel being fed.

- The air swept fuel distributor directs the volume of fuel being fired.

- A distributor setting device determines the positioning of the fuel trajectory plate.

- The distribution trajectory plate allows for lateral and longitudinal fuel distribution into the furnace.

- The fuel distributor opening located adjacent to the boiler front, is completely air cooled.

- A metering damper allows adjustment of air flow for proper front-to-rear fuel distribution.

- An overfire air system is strategically located to provide turbulence and through mixing of the volatile gases, thus enhancing the combustion process.

- A char recovery system of the straight-through pneumatic type is furnished with all necessary steel pipe, fittings, supports, and heat resistant alloy iron reinjection nozzles.

- The air pressure chamber, completely sealed both front and rear to prevent air leakage, directs and distributes hot combustion air through the active grate surface.

- Undergrate access doors, located front and rear of the air pressure chamber, provide inspection and access to grates.

- A furnace access door allows inspection and access to the grates.

Operation

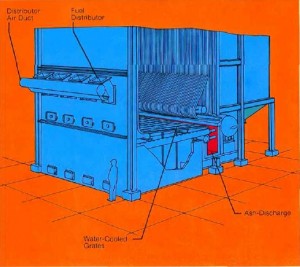

Fuel is continuously and automatically fed from the fuel chute into the air-swept fuel distributors where it is advanced across a specially-designed trajectory plate into the furnace. Fuel distribution, front-to-rear and laterally within the furnace, is controlled by combination setting of high-pressure transport air and trajectory plate angle setting. Strategically-located, high-pressure overfire air jets provide turbulence and through mixing of fuel/air to enhance the combustion process.

Fuel is continuously and automatically fed from the fuel chute into the air-swept fuel distributors where it is advanced across a specially-designed trajectory plate into the furnace. Fuel distribution, front-to-rear and laterally within the furnace, is controlled by combination setting of high-pressure transport air and trajectory plate angle setting. Strategically-located, high-pressure overfire air jets provide turbulence and through mixing of fuel/air to enhance the combustion process.

As a further aid to complete combustion, hot combustion air is evenly distributed through the active grate surface. Fine particles of fuel are rapidly burned in suspension while coarser, heavier particles are spread evenly on the water-cooled stationary grate, forming a thin, fast burning fuel bed.

Any ash formed is removed by steam or air nozzles located throughout the grate surface, and transported down the inclined grate surface into the ash-discharge opening.

Stationary water-cooled grate spreader stokers are designed for a variety of boiler designed for a variety of boiler designs firing low-ash fuels. Boiler grate heat-release rate is normally limited to 950,00 Btu/sq. ft.

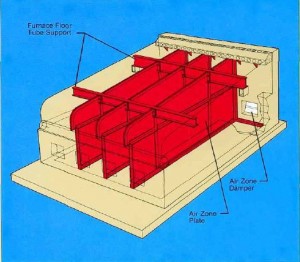

Grate sections are mounted, supported, and cooled by furnace floor tubes. Air and duel seals are provided around the perimeter for efficient boiler/stoker operation.

Individual air zones are provided across the width of the stoker for select proportioning of undergrate combustion air.