A major refinery in the United States has selected Indeck Keystone Energy, LLC (IKE) to supply a severe duty Fluidized Catalytic Cracking Unit (FCCU) flue gas cooler (FGC). The FCCU FGC's operate in a highly abrasive and corrosive environment. Indeck has successfully worked with this client multiple times to supply proven FCCU flue gas cooler designs. The boiler and auxiliary equipment were delivered and were successfully started up.

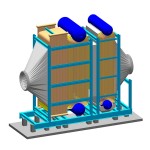

To minimize the installation duration, the superheater and boiler modules were manufactured as assembled modules for setting on the customer's foundations. Each system consisted of superheater modules integrated into the High Pressure (HP) boiler module, a Low Pressure (LP) Boiler module, and associated ductwork. Client feedback was incorporated in new design innovations based on site specific operating conditions for each design in order to improve access, cleanability , and reliability. Indeck's design has proven thermal performance and reliability.

From 710,000 lb / hr. FCCU flue gas flow at 1035 º F. and 230 º F. feedwater:

HP superheated steam flow is 68,500 lb / hr. - Design pressure is 750 psig.

LP steam flow is 29,500 lb / hr. - Design pressure is 125 psig

Flue gas design pressure is 5 psig. - Tube and membrane wall construction